Digital twin technology, an innovative leap in how we interact with the physical world through digital simulations, is rapidly gaining traction across various industries. At its core, a digital twin is a virtual model designed to accurately reflect a physical object. This technology is not just about creating a digital replica of the physical world, but also about enabling real-time monitoring, maintenance, and testing without the need to be physically present.

The implications of digital twins are profound in sectors like manufacturing, automotive, healthcare, and urban planning. In manufacturing, digital twins are used to optimize the production process. By creating a digital replica of a production line, engineers can test different configurations and settings to find the most efficient setup without interrupting the actual production. This predictive maintenance predicts problems before they occur, reducing downtime and increasing productivity.

In the automotive industry, digital twins are revolutionizing design and testing. Automakers use digital twins to simulate how a vehicle will perform under various conditions without having to build multiple prototypes. This not only speeds up the development process but also reduces costs significantly. Furthermore, with the advent of autonomous vehicles, digital twins allow for safer testing of vehicle responses in an extensive array of driving scenarios without risk to human drivers.

Healthcare is another area where digital twins are making a mark. They are used to create detailed simulations of human organs to study diseases and test treatments in a controlled virtual environment. This application of digital twins could lead to breakthroughs in personalized medicine by allowing doctors to test how a specific body might react to a treatment before administering it.

Urban planning and smart city applications are also benefiting from digital twin technology. Cities can create digital replicas of themselves to optimize everything from traffic flow to energy consumption. For instance, a digital twin of a city can be used to simulate the impact of potential changes in infrastructure, such as the introduction of a new bus route or the construction of a new building, to ensure that these are beneficial before any real-world changes are made.

Despite the promising benefits, the widespread adoption of digital twins is not without challenges. One of the main hurdles is the significant data requirements. To create accurate digital replicas, vast amounts of data need to be collected and processed. This poses questions about data privacy and security, especially when sensitive information is involved. Moreover, the integration of digital twins requires substantial investment in technology and skilled personnel, which might be a barrier for smaller businesses.

Another challenge is the need for continual updates to ensure the digital twin remains an accurate replica of its physical counterpart. This requires ongoing data input and adjustment, which can be resource-intensive. However, as IoT technology advances and becomes more prevalent, the ease of data integration and model updating is expected to improve.

Digital twins hold the potential to transform how we design, build, operate, and repair our physical assets, offering tremendous advantages in terms of cost, efficiency, and performance. Their adoption is set to redefine industry standards and spark innovation, provided that challenges related to data and resource demands can be effectively managed. As industries continue to navigate these challenges, the future of digital twins looks promising, paving the way for more intelligent and responsive systems across the board.

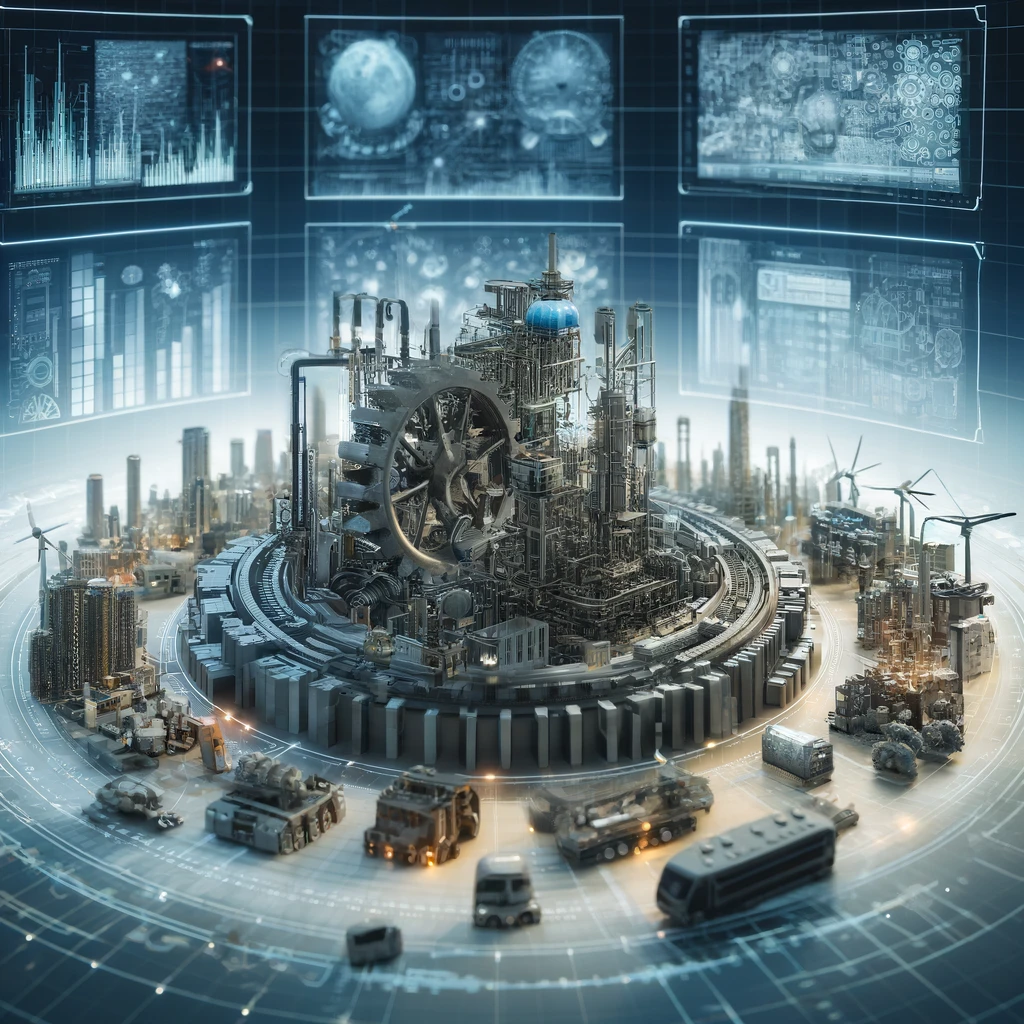

Feature Images:

Digital Twin adoption. It shows a central digital twin model with various industry applications around it.