In the realm of technological advancements, the concept of a Digital Twin has emerged as a groundbreaking innovation, reshaping how industries approach the lifecycle management of physical assets. Characterized by virtual replicas that mirror real-world objects, systems, or processes, Digital Twins facilitate a comprehensive understanding, tracking, and manipulation of assets across various sectors. With a significant 239% search growth, this concept reflects a burgeoning interest and recognition of its potential to drive efficiency, innovation, and sustainability.

At its core, a Digital Twin is a dynamic digital representation of a physical object or system, bridging the physical and digital worlds through data. These virtual models are constructed using sensors and real-time data to replicate the current state, functioning, and behavior of their physical counterparts. By integrating Internet of Things (IoT) technologies, machine learning, and analytics, Digital Twins offer unparalleled insights into performance, potential problems, and maintenance needs.

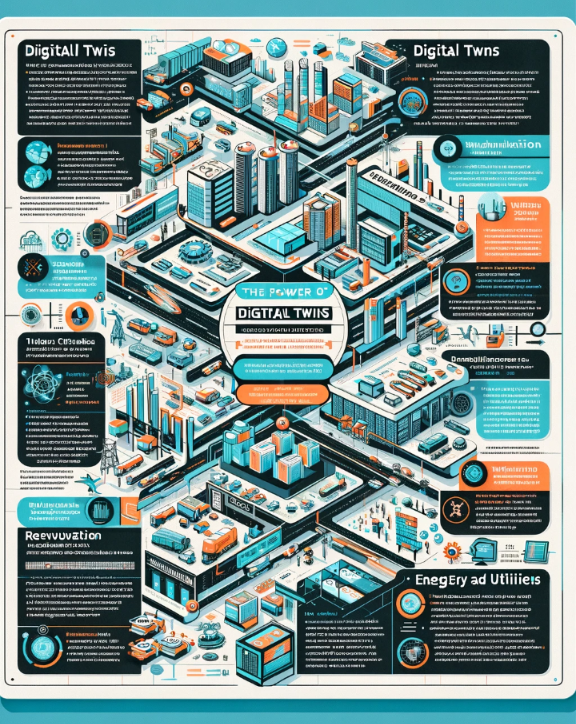

The versatility of Digital Twins has led to their widespread application across diverse industries, demonstrating their capacity to revolutionize traditional practices:

In manufacturing, Digital Twins optimize production processes, enhance product quality, and reduce downtime. They enable predictive maintenance, foreseeing equipment failures before they occur and allowing for timely interventions.

In healthcare, virtual replicas of organs or entire health systems can revolutionize personalized medicine, enabling doctors to simulate and assess the outcomes of treatments or surgical interventions before they are applied to the patient.

For urban development, Digital Twins facilitate the modeling of entire cities, improving infrastructure planning, energy management, and environmental sustainability. They enable city planners to simulate the impacts of various scenarios, from traffic flow to disaster response strategies.

In the energy sector, Digital Twins are pivotal in optimizing the performance of renewable energy sources, monitoring grid systems, and enhancing the reliability of energy distribution.

The adoption of Digital Twins propels industries towards greater innovation and efficiency. By providing a comprehensive view of assets throughout their lifecycle, Digital Twins enable organizations to make informed decisions, optimize operations, and reduce costs. Furthermore, they foster a culture of continuous improvement, with the ability to test and refine processes in a risk-free virtual environment before implementing changes in the real world.

Despite the promising potential of Digital Twins, their implementation is not without challenges. These include the need for high-quality, real-time data, integration with existing systems, and concerns regarding data security and privacy. Additionally, the complexity of creating accurate and comprehensive digital replicas requires significant expertise and resources.

Looking ahead, the future of Digital Twins appears bright, with advancements in AI, machine learning, and IoT technologies further enhancing their capabilities. As industries increasingly recognize the value of digital-physical convergence, Digital Twins are set to play a pivotal role in driving the next wave of digital transformation.

The concept of Digital Twins represents a paradigm shift in how industries manage and interact with physical assets, offering a powerful tool for innovation, efficiency, and sustainability. With their ability to replicate and simulate the real world in unprecedented detail, Digital Twins are not just a technological novelty but a fundamental component of future-ready industries. As we continue to navigate the digital age, the exploration and expansion of Digital Twin applications will undoubtedly shape the landscape of various sectors, heralding a new era of industry 4.0.